The best filter for clean food that perfectly meets the HACCP certification standards

How is compressed air (filter) used in food manufacturing?

-

01Container cleaning and sterilization

Containers such as injected plastic and glass bottles Bubble + compressed air cleaning, After chemical and UV sterilization, pressurized air Spray to dry quickly.

-

02powder transfer

Powdered milk, powder, etc. It can be transported to each place of use.

-

03packing

Open the lid or stopper with strong pressure. It can be moved and sealed.

-

04control valve

Essentially used in automation facilities Control valve with compressed air You can use it to adjust.

-

05air blade

Airblades for various purposes Can be used

-

06vacuum container making

After making the external mold, according to the internal shape spraying compressed air to can be crafted.

-

07carbon dioxide injection

by compressing carbon dioxide You can spray hard.

-

08cleaning

In food manufacturing facilities, soil or Remove dust by using an air gun can be cleaned.

-

09food manufacturing

Compressed air for milk, ice cream, etc. You can use it to mix the product evenly.

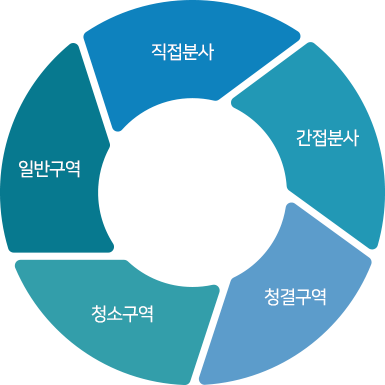

Perfect response to food HACCP standards

-

General/Small

Korea Food Safety Management Certification Institute Compressed air management plan Perfect response

HACCP

antibacterial coating

Heavy metal not detected

(dissolution standard certification)

Excellent microbial reduction effect -

Small, general HACCP certification,

Follow-up management, hygiene inspection, re-certification prepareIssuance of product certificate

Free consulting on compressed air management, such as installation location and specifications by use Follow-up hygiene check

Compressed air management ledger form provided, quality monitoring using Purity (AM01) Recertification

Installation location, follow-up management for re-certification: 1 year free A/S, 1:1 new product exchange at 1/2 price after 1 yearApplication case

International standards for compressed air such as filters

-

ISO 8573 - ISO 12500

-

ex01

Compressed air management international certification standard ISO8573~1~7

ISO 8573 : Standards to classify hazardous substance types, specify air quality levels, and measure pollutants

ex02Microbial testing during compressed air management ISO8573-7

Test condition (example) and unit: 1 bar, cfu/m3 (bacteria, yeast, etc.)

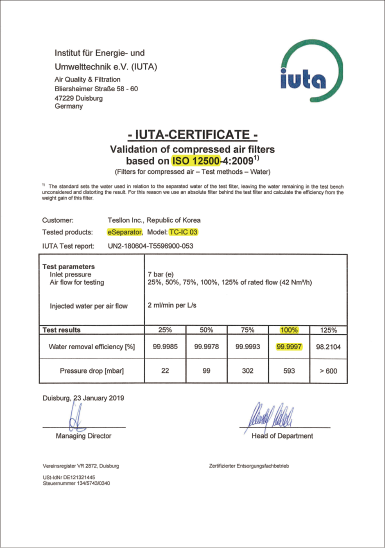

ex03Compressed air filter performance international certification standard ISO12500-4

ISO 12500 : Standards to test and evaluate the performance of compressed air filters [oil aerosol, oil vapor, particulate (dust), water (moisture)]

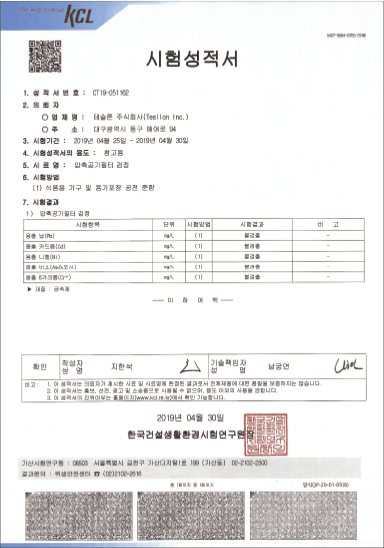

ex04Dissolution standard of compressed air filter

Heavy metal and hazardous substance dissolution standard test report suitable for food production environment (Can refer to standards for domestic utensils and containers and packaging)

-

filter performance

ISO 12500-4

-

filter harmful substances

Heavy metal, elution standard

-

microbial reduction

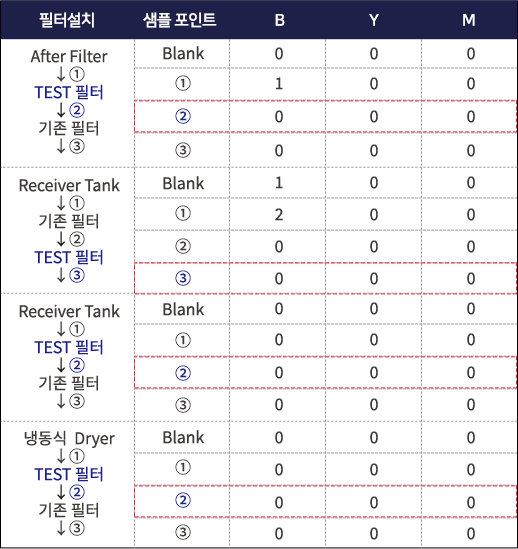

Microbial test results of a large domestic food company (Company L)

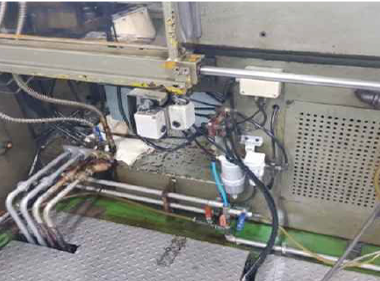

Example of filter installation

1. Filters, etc., are periodically cleaned of lubricants, moisture, etc., or compressed air is hygienically managed by replacement, and the used filter is confirmed with a test report to ensure that there is no risk of harm to food.

2. Periodic monitoring is carried out according to filter specifications (usage time, etc.) and the exchange cycle is readjusted The filter exchange cycle can be lengthened or shortened depending on the frequency of use