The pinnacle of industrial air filters

Reduce the defect rate lower power cost

Compressed air is air in the atmosphere compressed by a compressor. The compressed air through the compressor removes moisture and foreign substances in the air and

It sucks in the lubricant and reduces the quality of the compressed air. Compressed air is the second most used energy after electricity in industry.

Used for powder transfer, milling, operation of control valves, residue left after processing, or when clothing or body is contaminated by dust, use an air gun.

It is often used for cleaning and cleaning.

However, the air contains harmful foreign substances such as fine dust and heavy metals, and substances that may propagate such as microorganisms.

If compressed, very high concentrations of harmful substances are present inside the compressed air.

Possible problems when compressed air quality is poor

If the quality of the compressed air is poor, the overall maintenance cost may increase, and in severe cases, the equipment itself may be damaged.

-

pipe corrosion

pipe corrosionIf the moisture in the compressed air is not filtered properly, the pipe is corroded and the air is Leaks or corroded debris can break off and be blown out with compressed air.

-

valve sticking

valve stickingOil and moisture in the compressed air are stuck to valves such as solenoid valves. This may cause product quality deterioration, product defects, and safety accidents.

-

instrument blockage

instrument blockageThe inlet to the sensor is blocked with oil or foreign substances, so that the accurate reading is not possible. You may not get results.

-

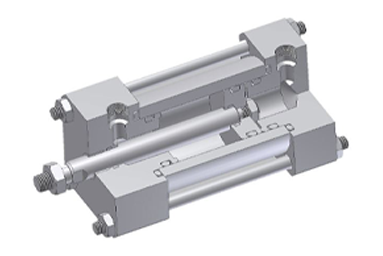

Malfunction of pneumatic equipment

Malfunction of pneumatic equipmentDue to the inner diameter of the tube of the pneumatic device or the adhesion of the fitting hole, the pneumatic cylinder Malfunctions may occur, which may reduce the life of the cylinder.

-

Pneumatic motor and tool performance degradation

Pneumatic motor and tool performance degradationIf moisture or oil enters the inside of the pneumatic motor and pneumatic tool, water and oil Failure due to sticking or wear caused by overheating or foreign substances This may cause performance degradation.

-

stop production line

stop production lineDue to the contaminated compressed air, the above errors continue in the production line, resulting in This may cause the production line to stop.

-

overflow

overflowOverflow during night production or when there are no workers due to freezing of pneumatic equipment in winter When this phenomenon occurs, moisture goes over the line and causes a very big problem.