Purity

Korea’s first compressed air air quality measurement kit

quality (quality) + Purity (purity) Real-time, anyone can monitor immediately

You can check the quality of compressed air at low cost.

-

HACCP hygiene management

-

Easy way to measure

-

Real-time check available

-

Affordable price

-

Possible to check whether food is indirectly sprayed

The most convenient and most reliable compressed air quality control measurement kit

HACCP Perfect response solution

Due to the nature of compressed air piping, it is difficult to check the degree of contamination because the inside is opaque.

“After the problem occurred, I checked and started managing”

This reactive response is costly and time consuming.

On the other hand, Purity can conveniently measure the quality of compressed air and check it in real time without expensive equipment.

(Available to measure microorganisms, oil, and foreign substances)

-

Chapter 01

Compressed air moisture management -

Chapter 02

Compressed air dew point management

Comparison before/after monitoring

-

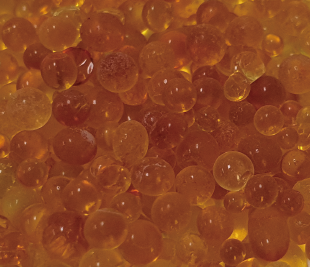

Before monitoring

-

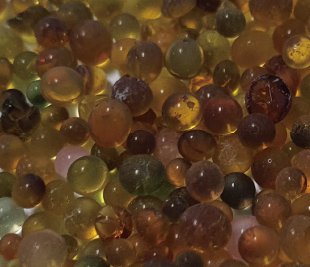

After monitoring

HACCP custom solution

Stage 1 (moisture)

-

No moisture condensation on top surface

If transparent, suitable -

Moisture condensation on the upper surface

If it turns hazy, unsuitable

Stage 2 (stalls)

-

Even after 1 minute, the color of the silica gel

If it doesn't change suitable -

Some silica gel colors in 10 minutes

If discolored unsuitable

Changing the future of compressed air

The new AM01 measures the quality of compressed air.

Periodic compressed air management (measurement) required for HACCP certification, hygiene inspection, and re-certification

HACCP Compressed Air Management Procedure

-

1. Confirmation of use and cross-contamination of compressed air

-

2. Establishment of compressed air hygiene management standards

-

3. Periodic inspection management (monitoring, facility and cleanliness management, etc.)

Compressed air quality control

HACCP Food Indirect Spraying Criteria

company side

-

01

Manufacture of hygienic

and safe food -

02

Systematic hygiene management /

reliability improvement

consumer side

-

01

Provide safe food to consumers

-

02

Opportunity to choose food

Necessity of compressed air management

Due to the nature of compressed air piping, it is difficult to check the degree of contamination as the piping is opaque.

Dealing with these problems after they occur requires a huge amount of money and time

Problems and Disadvantages of Existing Products

-

short-lived

Because it is a one-time measurement, outside the measurement time In response to the ever-changing flow rate Risks that occur cannot be prevented.

-

intractable

Sensitive to foreign matter and measuring very cumbersome

(line off, measured over 1-20 hours) -

complicacy

Data analysis is very complex, common worker It's hard to do.

-

high price

Existing products are burdensome in excess of tens of thousands of dollars.

의 장점

의 장점

-

in real time

Because the process of change is visible in real time You don't have to wait a long time.

-

everyone

Because it is very simple to use Anyone can use it easily.

-

easily

to the existing air piping Because you can just connect There are no cumbersome and difficult processes.

-

immediately

How long does it take to get results It's only 10 minutes, so The line can be restarted immediately after the test.